About quality control

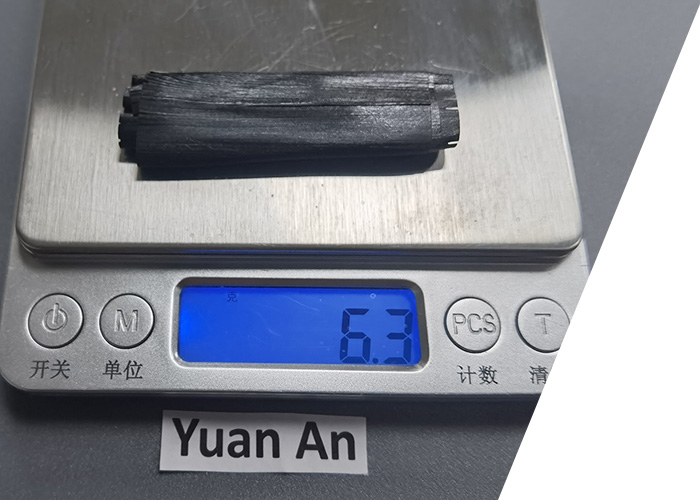

MATERIAL WEIGHING

Carbon fiber prepreg is measured in rolls per (150 m), we use every 150 square meters of material to detect the average weight of 10 square centimeters, and defect whether the resin content is average or not, to ensure that in the subsequent use of the material can meet the weight requirements and required strength ratio.

ENVIRONMENTAL HEALTH

ENVIRONMENTAL HEALTH

In order to make every rim to be high-quality ,every production link and workshop and equipment, mold hygiene is essential. It's about the stability of the product and the appearance of the rim.

TEMPERATURE CONTROL

We use large refrigeration equipment to keep the workshop at 25 ℃,24/7 ,in order to allow carbon fiber to be made at the temperature that works best for it.

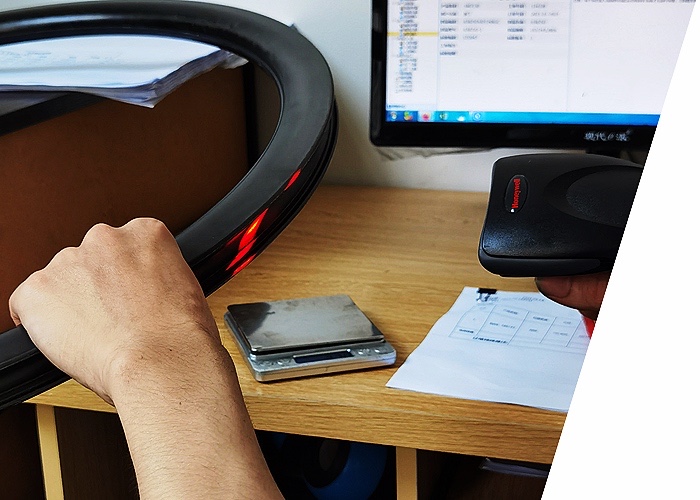

WEIGHT CONTROL

WEIGHT CONTROL

At the end of each production link, it is necessary to confirm the rim weight of this step before moving on to the next step.during this period, we need 8 times of weight testing to meet the quality inspection and shipment standards.

DEFORMATION TEST

After passing the tire pressure test, will do the tire pressure deformation test, deformation needs to be less than 0.2mm before entering the drilling step.

TIRE PRESSURE

TIRE PRESSURE

Every rim is tire loaded and tested for tire pressure.

PAINT INSPECTION

Check whether there are particles on the paint surface of the rim and whether the decal is consistent with the customer's profile.

SPOKE TENSION CHECK

SPOKE TENSION CHECK

Check whether the tension of each spoke is within ±5kgf.

CONFIRMATION OF INFORMATION

Final confirmation of customer receipt information.