UNC 29er MTB wheelset cross country Ultralight rims pro MTB hub

- yuan an

- xiamen

- 7-15days

- 1000pair

Ultralight Non-Coated,which means the rims are original natural carbon surface ,without any coatings/painting .

SPECIFICATIONS

RIM SPOKE

SERIES: UNC-MTB FRONT SPOKE PATTERN: Two-cross

RIM TYPE: Hookless&asymmetric REAR SPOKE PATTERN: Two-cross

RIM WIDTH: 28mm(22.5mm inner width) SPOKE COUNT: 28F/28R

RIM DEPTH: 24mm SPOKE TYPE: Sapim cx ray

USE: XC NIPPLE TYPE: Sapim secure lock

HUB OTHER

FRONT HUB: 15*100mm/15*110mm ASSEMBLY METHOD: Handbuilt

REAR HUB: 12*142mm/12*148mm EXTRAS: Spokes and nipples

BRAKE INTERFACE:6 bolt lock WEIGHT: 1195g±30g(sapim spokes#xd freebody)

FREEBODY:Shimano (HG)&XD&Micro spline (MS) SYSTEM WEIGHT LIMIT: 110kg

FREEBODY STRUCTURE: Ratchet system 36T

What is a UNC carbon rim?

UNC is Ultralight Non-Coated,which means the rims are original natural carbon surface ,without any coatings/painting .

First of all,regular rims from the mold,need a lot of processing links:grinding,drilling,painting,labeling,to the final shipment.Of course,during this process,each rim needs to go through with a number of links of quality testing including the flatness testing,roundness testing,weight testing,as well as tire pressure testing and so on.

But the non-coated rims are taken out from the mold,then drilled directly,tested,and labeled directly,shipped.It means we remove the“coating”link from the whole production process,which would be a necessary part of the appearance processing of regular rims for all of the manufacture.However,we have broken through this.

Although it’s without any coating processing,our UNC rims still retains a fine appearance comparable to that of coated rims;there is no need to add extra coating to mask defects;and more importantly,the non-coated rim appearance provides a more clear natural carbon fiber texture,with carbon lines more clearly displayed.

In addition,to a coating process of a finished rim requires 36 steps,5-7 days,during the period,the rim needs to go through 150.320.400.600.800.2000.2500 sandpaper polishing,and the non-coated rims greatly reduces the labor time also has a great protection to the environment.

But it wasn’t that easy,and it took us two years to develop and test for this project,this was a huge challenge.

Features?

Since the unpainted rims are not polished and painted,the carbon fiber filaments are not damaged,thus guaranteeing the initial strength of the rims.The surface of the rims also has only the gloss of the resin contained in the carbon cloth,which lasts longer than the gloss of the paint.At the same time,due to the mold surface has a release agent,in the daily washing for rims surface,it saves more time,the rim is also not easy to be glued by dust.

How did we do that?

All rims production can not be separated from molds and materials,we have carried out a lot of research and development in both directions.

First of all,we use(high-precision mold)labeled“NAK80 steel”,high-strength mold can ensure that after being used for many times,mold tolerances are still in the best accuracy range,while adding a special resin flow groove on the new mold,which makes the resin of each rim more uniform.

It is worth noting that the weight of the three non-coated rims compared to ordinary molds reduced by 80g-100g,which is very amazing!

Second,there are special changes in the material,it is well known that Japan’s Toray carbon fiber is the best in the world,we call it as carbon fiberprecursor,because the imported material is only semi-finished products,we have to re-create these carbon fiberprecursor,so that it can be used as carbon fiber cloth,and eventually used for rim production.

In general,producing rims is like building a building,a skyscraper that requires the strongest concrete and steel bars to build.carbon fiberprecursoris like steel bars,the resin is like concrete.And about the resin,we have independently developed a special resin,combined with T700.T800 carbon fiberprecursor,upgrade the total quality for the carbon cloth,and finally formed the most suitable material for bicycle rims,which can make our rims glowing,while reaching ultralight weight!

TECHNOLOGY

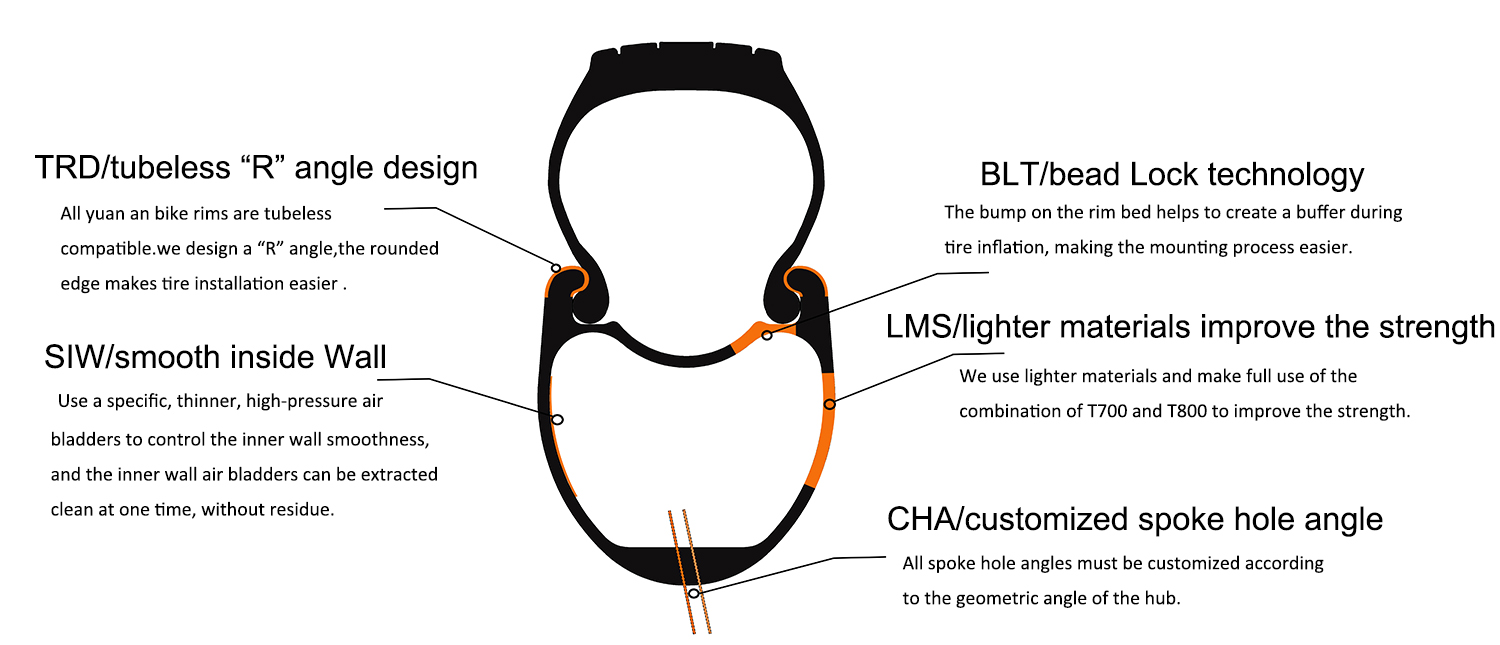

CHA/Customized spoke hole angle

All spoke hole angles must be customized according to the geometric angle of the hub.all drilled holes are inspected to ensure they are free of burrs.You can request a customized drilling pattern if you have a unique wheel build.

TRD/Tubeless R angle design

All yuan an bike are tubeless compatible.We design a R angle,The rounded edge makes tire installation easier and offers increased support during hard cornering with a softer edge and larger surface area.

LMS/lighter materials improve the strength

We use lighter materials and make full use of the combination of T700 and T800 to improve the strength.

SIW/smooth Inside Wall

We use a specific, thinner, high-pressure air bladders to control the inner wall smoothness, and the inner wall air bladders can be extracted clean at one time, without residue, not only effectively improve the tightness of the carbon fiber yarn, but also allow the spoke cap to be more tightly integrated with the spoke hole.

OPT/one piece technology

Compared to the technology of 3 piece, our one piece tech is more technically difficult and takes longer to produce, but the rigidity of the rim is at least 7% higher.

BLT/Bead Lock technology

The bump on the rim bed helps to create a buffer during tire inflation, making the mounting process easier. When the tire is mounted, the raised portion reinforces the tire bead, making it harder to “burp” or fall back into the drop channel.

URT/Unique resin technology

To improve the stability of the wheel, we think the material control is the root.So we import carbon fiber raw yarn from Toray, Japan, and mix with the high-temperature-resistant resin which researched and developed by our own, weaving them to be prepreg .So, from the source we firmly control the quality.

HBW/Hand bulit wheel

From prototype to production, every wheel gets assembled by hand. There is no substitute for the experience and meticulous attention to detail that a human being brings to the craft of wheel building.

EPT/Environmental protection technology demoulding

Compared with many oil-based mold release agents, we use a neutral mold release agent imported from Germany, because we use (high-precision mold) labeled "NAK80 steel", which is a very high-strength abrasive tool, compared to ordinary P40 For steel, NAK80 has a firmer surface and a smoother rim surface.